Our Capabilities

Itero is a holistic access provider, allowing our highly qualified and experienced team to provide the most appropriate access systems for each project.

EONCOAT

The Permanent Corrosion Solution

Itero Australia are now certified applicators of EonCoat, a revolutionary product changing the game in the industrial coating industry. EonCoat is a spray-applied coating that permanently prevents rust and corrosion on carbon steel.

EonCoat is suitable for a wide range of industries that rely on carbon steel assets, from oil and gas to marine applications. Apply at the beginning of an asset's life or restore your corroding asset effectively by applying directly to tightly-bonded surface rust. This product is less expensive to apply and also saves future maintenance costs by creating a permanent barrier that prevents rust and corrosion from developing. It is our product of choice in providing long-term asset protection.

EonCoat not only protects carbon steel assets, but also the safety of our team. The coatings are water-based, made with non-toxic materials, safe for our people and better for the environment all without compromising coating longevity or performance.

EonCoat is a reliable and responsible, cost-effective corrosion prevention solution.

WHAT WE DO

Itero has regularly assembled and supplied a team covering all of the below trades to our clients construction projects. This highly skilled team has been highly effective and conducting trade support in areas complicated by access in a very short turnaround which has been instrumental to our clients in reducing delays and responding quickly of out of sequence tasks.

Capabilities Include:

- Advanced Rigging, Installation and Removal of complex structures

- Mechanical Fitting & Coded Welding

- E&I, Cable Installation Support

- Painting/Coating Remediation

- Testing & Commissioning

- NDT Inspections

As the name suggests, Itero is committed to rejuvenating buildings and structures that are nearing a critical stage in their lifespan so that they can continue to be of value for our clients for many years to come. Our expertise in remediation and maintenance provides significant cost and time savings in comparison to new-build replacements.

Equipped with all the necessary access methods and trade personnel, Itero’s remediation team can facilitate every aspect of inspection, maintenance and rectification for our clients.

Capabilities Include:

- Inspection and Reporting

- Waterproofing

- Concrete Remediation

- Painting

- Glazing

- Façade Carpentry, Cladding Removal and Installation

- Design, Installation & Certification of Height Safety/Access Systems

- Preventative Maintenance and Cleaning

- Advanced Rigging & scaffolding

- Mechanical Fitting & Coded Welding

- E&I, Cable Installation Support

- NDT Inspections

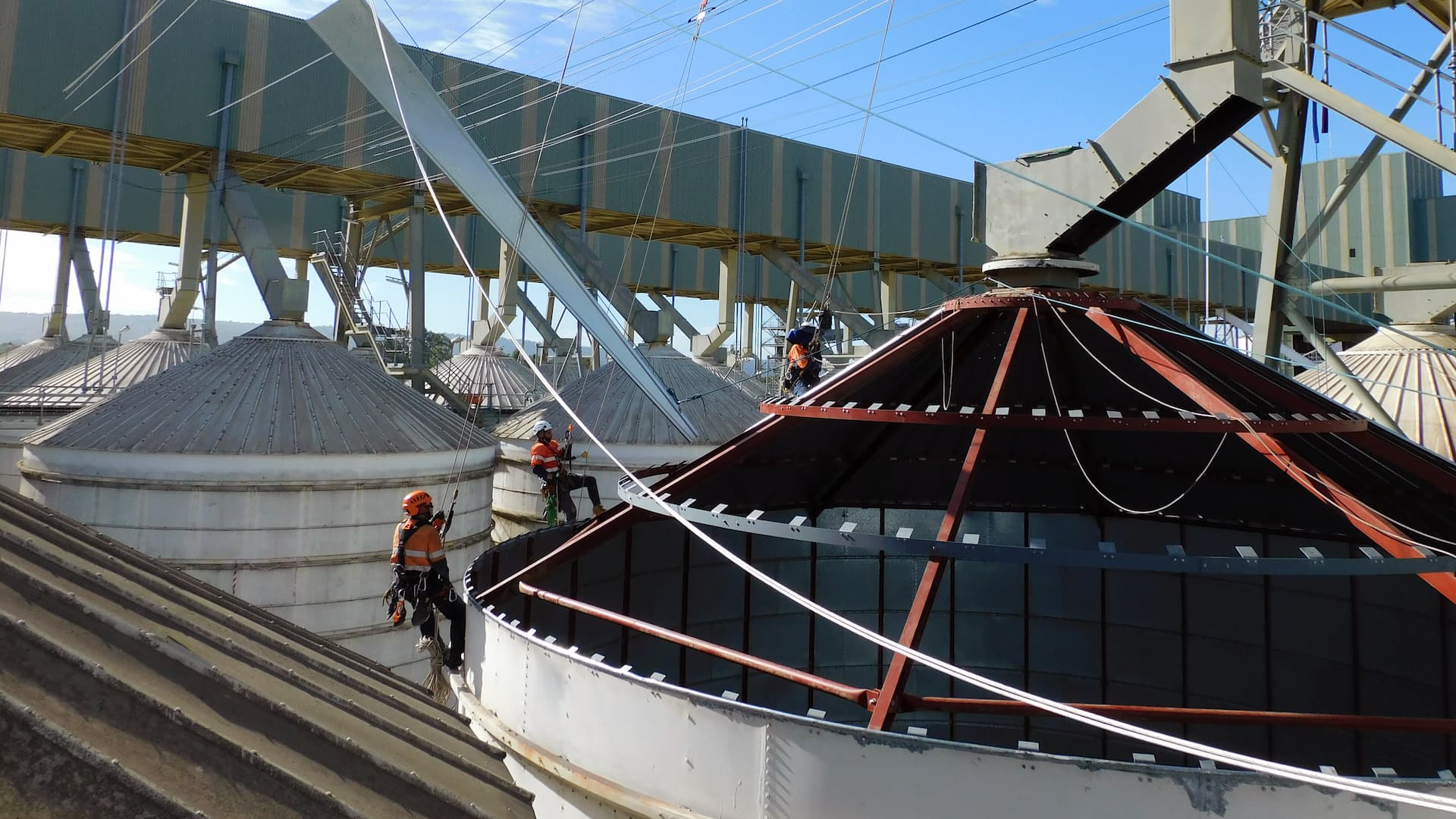

Due to Itero’s available full-time team, we can rapidly mobilise required Rope Access trades to urgent projects at short notice. Itero’s operators have many years of experience in oil and gas, offshore, mining and industrial maintenance, shutdowns and major projects. Itero’s team of IRATA certified access technicians are highly suited for regular inspections and preventative maintenance of mining facilities, plants, equipment or infrastructure to ensure any integrity issues can be identified and addressed early.

Trade capabilities available for shutdown maintenance & projects include:

- Advanced Rigging, Installation and Removal of complex structures

- Mechanical Fitting & Coded Welding

- E&I, Cable Installation Support

- Painting/Coating Remediation

- Concrete Remediation

- Testing & Commissioning

- NDT Inspections

Itero regularly provides inspection services to our clients and engineering firms to access the areas that are difficult to inspect and assess in a quality and quantitative fashion. Our team of highly experienced industry experts can provide the below inspection services whilst also providing accurate budget assessments for rectification.

- Dilapidation Reports

- Integrity Reports

- Non-Destructive Testing

- Drone Surveys

- OH&S Compliance Reports

- Development of Rectification Methodology and Scope Of Works

- Project Completion, Quality Control Documentation and Warranty Documents

Applying protective coatings go hand in hand with asset remediation projects to increase the corrosive resistance, waterproofing and overall image of the asset. Our expert staff will provide the most sensible product selection, surface preparation and application method to guarantee a quality finish whilst significantly enhancing your asset’s working lifespan and operational performance. We are also endorsed as accredited applicators of EONCOAT, Dulux and Parchem with which we work closely with to complete our projects to a high standard and achieve long term product and application warranties.

Itero’s specialised equipment is uniquely targeted at conducting coating application projects in difficult to reach areas. This gives our project team a greater ability at managing the risks and challenges associated with these projects.

Itero has a large team of applicators with extensive experience in the following project applications:

- Corrosion control

- Industrial protective coating systems

- Sprayable/liquid applied membrane systems

- Airtight sealing systems

- Friction/wear reduction

- Plural component systems

- Graffiti removal

- Heritage asset rectification

- Industrial blasting and painting

We believe that concrete should be built to last. Unfortunately in some cases our clients’ assets, across all sectors, are often hit with defects, concrete cancer, and corrosion. Itero can provide an investigational assessment of the area(s) affected, then work with durability consultants and material suppliers to develop specification solutions that will, in most cases, outperform the life of the structure. It is our mission to provide the best possible solution that will combat various environmental challenges, and extend the life and durability of our clients’ assets.

- Cementitious And Epoxy-Based Reinstatement Repair Mortars

- Cementitious And Epoxy-Based Grouting Systems

- Floor & Pavement Concrete Repair Systems

- Low In Concrete Cover Repair Systems

- Crack Repairs specialised Injection Systems

- Cathodic Protection Systems

Itero has extensive experience in waterproofing investigation and rectification solutions. It is a fact that nearly every structural asset will require some form of waterproofing system to prevent water ingress and commonly the areas that require these solutions are difficult to access. Using a combination of access methods our team of accredited applicators regularly apply waterproofing solutions to provide our clients’ structures with the best protection against unwanted water and moisture ingress.

Itero is experienced in the selection and quality application of the following types of waterproofing systems:

- Sprayable/liquid applied membrane solutions

- Cementitious membrane solutions

- Sheet applied solutions

- Industrial joint sealant systems