Corrosion is an inevitable challenge in industrial environments, impacting infrastructure integrity, safety, and long-term costs. When corrosion is detected, asset owners face a critical decision—should they conduct ongoing maintenance or opt for full remediation? The right approach depends on factors such as the asset’s lifespan, structural impact, and cost-effectiveness.

The Importance of Corrosion Management

Corrosion is more than just an aesthetic issue; it weakens structures, causes equipment failures, and leads to costly downtime. Implementing the right corrosion management strategy can extend the life of assets, prevent deterioration, and reduce long-term expenses.

Key Factors to Consider

- Asset Lifespan – If an asset is nearing the end of its service life, ongoing maintenance may be enough. However, if it needs to remain operational for decades, remediation might be a better long-term investment.

- Extent of Damage – Surface corrosion can often be treated with localized maintenance, whereas severe deterioration may require a complete remediation strategy to restore structural integrity.

- Cost Considerations – While maintenance has a lower upfront cost, frequent repairs can add up over time. Investing in remediation may be more cost-effective in the long run by preventing future issues.

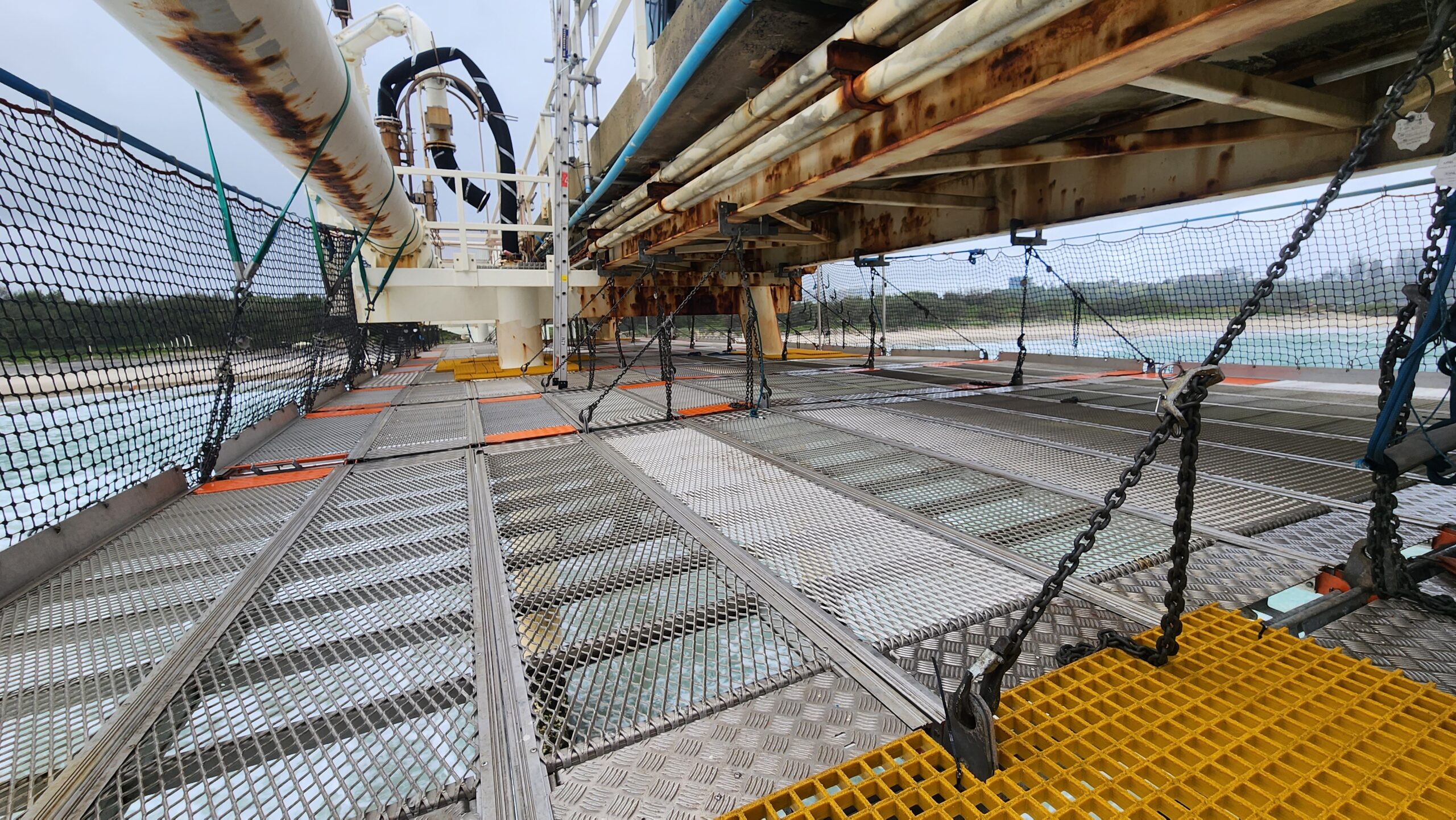

- Operational Impact – Some corrosion management methods require shutting down operations, which can be costly. Innovative access solutions like rope access and V-Deck™ minimise downtime while still allowing for effective remediation.

Maintenance vs. Full Remediation: What’s the Difference?

Maintenance strategies focus on managing corrosion to slow its progression, using surface treatments, localised coatings, and inhibitors. These methods are ideal for minor corrosion issues and when regular upkeep is feasible.

Full remediation, on the other hand, involves restoring an asset to its original condition by conducting structural repairs, replacing damaged materials, and applying full recoating systems. This is a long-term investment that reduces the need for frequent maintenance and extends asset life.

While maintenance is a short-term, lower-cost solution, remediation provides greater durability and protection against future corrosion-related failures. Choosing the right approach depends on the asset’s condition, operational needs, and budget.

Innovative Solutions for Corrosion Management

At Itero Australia, we specialize in advanced corrosion control techniques that combine efficiency with cost-effectiveness. Our IRATA-certified rope access technicians and cutting-edge access solutions like V-Deck™ allow us to perform corrosion remediation with minimal disruption to operations.

By leveraging modern coating technologies, proactive inspection programs, and customized access strategies, we help asset owners make informed decisions that optimise long-term performance.

Choosing the Right Strategy for Your Assets

Every asset is unique, and there is no one-size-fits-all approach to corrosion management. A thorough corrosion assessment is essential to determine whether maintenance or remediation is the best solution.

Need expert guidance on managing corrosion? Contact Itero Australia today to discuss how we can help protect and extend the life of your critical infrastructure.